VIN check before buying: carVertical −20% discount

VIN check before buying: carVertical −20% discount

When buying a used car, you don’t want one with heavy accident history. Bodywork can be done so well that the car looks brand-new. The reliable way to know is to measure the paint with a thickness gauge. We use it every day across Germany (especially Berlin & Brandenburg) to give clients a transparent history. Listings often say “unfallfrei” (“accident-free”), but definitions vary: small repairs may “not count”, and less honest sellers omit crashes. Measuring the paint yourself or hiring experts is the most reliable path.

Why a paint thickness gauge matters

A paint gauge measures coating thickness. Types include magnetic (simple, imprecise), electromagnetic (more accurate; works on steel and aluminium) and ultrasonic (more expensive; can read on plastics). For car buying, a compact electromagnetic Fe/Al gauge is typically enough.

From factory, paint is even. Most cars show about 90–160 μm (local spots up to ~180–200 μm). Considerably higher numbers mean a respray; multiples often indicate body filler. A respray alone isn’t a deal-breaker (scratches, hail). But filler and a “layer cake” on structural elements are red flags—check geometry and history. ECU/airbag scans also help.

From practice: a flawless-looking car showed ~800 μm on the roof—thick filler under the paint. Later we learned it had rolled over.

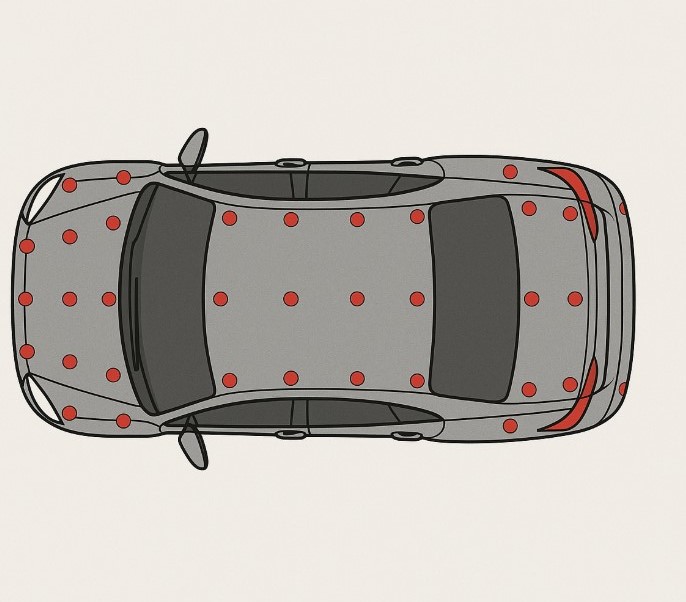

Where and how to measure

- Calibrate the gauge using the reference foils per the manual—otherwise readings won’t be trustworthy.

- Measure each panel at least in 5 spots (corners + center) and take 2–3 readings per spot—use the average.

- Probe perpendicular on a clean surface: tilt/dirt inflates numbers.

- Don’t skip the roof. Factory there is often 70–120 μm; outliers suggest hail/rollover.

- Check pillars and sills. Critical for safety—repairs here matter most.

- Materials. Aluminium is usually thinner; modern gauges show Fe/Al. If the bonnet “suddenly reads Fe” on an aluminium car—likely replaced.

- Plastics. EM gauges don’t read plastic; ultrasonic is required. Cosmetic plastic work is less critical.

Decoding the readings

- ~200+ μm: likely respray (incl. clear coat). Inspect closely.

- 300–500 μm: high chance of filler—repairs done. On structural parts, it’s a serious risk.

- 700–900 μm: very thick “layer cake”, used to correct major deformation. Future cracking/peeling possible.

- 1000+ μm: almost certain heavy crash damage. Best avoided.

Judge the whole car: a single local respray is a bargaining point; a “chain” of high values on adjacent panels (fender+door+pillar) hints at a major hit.

Other repair clues

- Colour/finish mismatch: tone, gloss, orange-peel, runs.

- Disassembly marks: chipped paint on wing bolts, door hinges, bonnet latch.

- Uneven gaps: asymmetry suggests pulled chassis.

- Glass & lights: year codes should match the car.

- Rails & floor: fresh seams/sealant, irregular corrosion—signs of repairs.

The gauge is a tool, not a verdict. An expert correlates readings with visual and legal checks to give a confident recommendation.

Buying a car in Germany? We’ll check bodywork and history for you

Our Sicher-Check team works in Berlin, Potsdam and across Germany. You get:

- 🔎 Document & history check (VIN reports, damage photos, mileage).

- 🧲 Paint measurements with a 5-point-per-panel method.

- 💻 OBD diagnostics, fault scan, test drive.

- 📝 A written “buy / don’t buy” verdict + bargaining arguments.

- 💬 English / German / Polish / Ukrainian.

- 💶 Transparent prices and a request form online.

Werbung / *Affiliate-Link

Links and banners marked with an asterisk (*) are affiliate links/banners. If you use such a link and subsequently request an offer, sign a contract or make a purchase, we receive a commission from the respective provider. For you, there are no disadvantages: the price and conditions remain the same.

Reference paint thickness: steel vs aluminium

Values are averages and depend on model/plant. Compare panels on the same car and look for “chains” of anomalies.

| Material | Panel | Factory thickness, μm | Acceptable variation | Be cautious if | Comment |

|---|---|---|---|---|---|

| Steel (Fe) | Fender/door/bonnet | 90–160 | up to ~180–200 | >220 — likely respray; >300 — filler |

Compare left/right sides and adjacent panels |

| Steel (Fe) | Roof | 70–120 | up to ~150–160 | >180 — hail/repair signs; >300 — filler |

Roof anomalies often point to rollover |

| Aluminium (Al) | Bonnet/fender/door | 60–110 | up to ~130–150 | >180 — respray; >280 — filler |

If the gauge reads “Fe” on an aluminium part — likely replaced |

| — | Plastic (bumpers etc.) | — | — | EM gauge won’t read | Ultrasonic required; plastic cosmetics are less critical |

Note: a single local respray = room to negotiate. A “chain” of high values (fender+door+pillar) = evidence of a major hit.

FAQ — frequently asked questions

Which paint gauge should I buy for pre-purchase checks?

An electromagnetic Fe/Al gauge covers most needs. If you must measure plastics, choose an ultrasonic gauge.

What’s a normal factory paint thickness?

Often 90–160 μm on steel with local spots up to ~180–200 μm. Aluminium is usually thinner. Readings of 300–500 μm suggest filler.

What if I see filler on pillars and sills?

It’s a marker of serious impact. We recommend a deeper geometry check; in most cases, walk away.

20% off carVertical*

20% off carVertical*

Choosing the best hybrids 2015–2025 on the German market

Choosing the best hybrids 2015–2025 on the German market